ISO-IEC 17025:2017 Recognized

ISO 9001:2015 Certified

1680 North Main Street

Orange, CA 92867

Phone: (714) 283-2032

10%

off

New clients receive

10% discount on first

sample submission

Accelerated Weathering Test Lab

Sunlight, heat and moisture can cause serious product deterioration–such as fading, color change, cracking, peeling, oxidation or loss of strength. Damage from weathering or corrosion occurs both outdoors and indoors, and its severity can vary greatly in different climates. Even materials that are resistant to sunlight alone or to moisture alone often fail when exposed to sunlight and moisture in combination.

Sunlight, heat and moisture can cause serious product deterioration–such as fading, color change, cracking, peeling, oxidation or loss of strength. Damage from weathering or corrosion occurs both outdoors and indoors, and its severity can vary greatly in different climates. Even materials that are resistant to sunlight alone or to moisture alone often fail when exposed to sunlight and moisture in combination.

CRT Labs now offers accelerated weathering testing using the latest Q-Lab weatherability testing equipment. Whether your need is to test the damaging wavelengths of light encountered either indoors or outdoors, or testing related to moisture exposure, CRT Labs has a solution.

Outdoor Exposure Testing Lab

CRT Laboratories Q-Sun Xenon Test Chamber reproduces the damaging wavelengths of light encountered either indoors or outdoors. Xenon lamps emit ultraviolet, visible and infrared light. Studies have show that filtered Xenon arc lamps are the best method to test products such as pigments, dyes and inks, which may be sensitive to the longer UV wavelengths and visible wavelengths of sunlight.

Accelerated Weathering Testing

In just a few days or weeks, with the use of the Q-Lab QUV Accelerated Weathering Tester, CRT Laboratories can reproduce damage that may occur over months or even years outdoors. The QUV is recognized as the most sophisticated equipment designed for this test.

UV Exposure Testing Lab

Ultraviolet light causes almost all the photo degradation to materials exposed outdoors. CRT Laboratories' outdoor exposure testing equipment reproduces only the UV portion of the spectrum. By using a UVA-340 lamp, we have the best available simulation of short-wave sunlight. The UVA-340 lamp's use is especially valuable when polymer testing to compare the performance of different types of polymers and stabilizers. It is also the best lamp for correlation studies.

Moisture Testing

Products outdoors can be exposed to moisture in the form of dew for up to 15 hours per day. CRT Laboratories' accelerated outdoor UV testing provides a rigorous, yet highly realistic, moisture exposure with cycles of hot condensing humidity. With the use of the QUV weatherability testing equipment, a spray can simulate the effects of rain, such as thermal shock and erosion, giving you realistic outdoor weathering exposure data.

Accelerated Weathering, Outdoor Exposure & Color Measurements

CRT Laboratories utilizes the Konica-Minolta (CM-700d Spectrophotometer handheld, portable color measurement instrument), which is designed to evaluate the color and appearance of samples very small to large in size, including objects with flat, shaped, or curved surfaces. This high precision, reliable spectrophotometer allows users to evaluate, reproduce, and control the color of pigments and dyes in a more effective, streamlined process. Its advanced capabilities help establish and meet color quality standards more efficiently, maintain consistency in each batch of material, and communicate color seamlessly internally and throughout the supply chain. This makes the CM-700d ideal for color analysis, formulation, quality control inspections, and process control procedures within research and manufacturing environments.

CRT Laboratories utilizes the Konica-Minolta (CM-700d Spectrophotometer handheld, portable color measurement instrument), which is designed to evaluate the color and appearance of samples very small to large in size, including objects with flat, shaped, or curved surfaces. This high precision, reliable spectrophotometer allows users to evaluate, reproduce, and control the color of pigments and dyes in a more effective, streamlined process. Its advanced capabilities help establish and meet color quality standards more efficiently, maintain consistency in each batch of material, and communicate color seamlessly internally and throughout the supply chain. This makes the CM-700d ideal for color analysis, formulation, quality control inspections, and process control procedures within research and manufacturing environments.

The CM-700d Spectrophotometer is compatible with SpectraMagic NX software to record measurements and provide a more comprehensive color analysis, as well as Colibri software to formulate color recipes for various applications. For dermatological applications, the CM-700d can also be used with CM-SA Skin Analysis software.

The following specifications are included with this instrument: di: 8°, de: 8° (diffused illumination, 8° viewing angle), SCI (specular component included)/SCE (specular component excluded) selectable with automatic switching (Conforms to CIE No. 15, ISO 7724/1, DIN5033 Teil7, ASTM E 1164, and JIS Z 8722)

CRT Laboratories utilizes the Konica-Minolta (CM-700d Spectrophotometer handheld, portable color measurement instrument), which is designed to evaluate the color and appearance of samples very small to large in size, including objects with flat, shaped, or curved surfaces. This high precision, reliable spectrophotometer allows users to evaluate, reproduce, and control the color of pigments and dyes in a more effective, streamlined process. Its advanced capabilities help establish and meet color quality standards more efficiently, maintain consistency in each batch of material, and communicate color seamlessly internally and throughout the supply chain. This makes the CM-700d ideal for color analysis, formulation, quality control inspections, and process control procedures within research and manufacturing environments.

The CM-700d Spectrophotometer is compatible with SpectraMagic NX software to record measurements and provide a more comprehensive color analysis, as well as Colibri software to formulate color recipes for various applications. For dermatological applications, the CM-700d can also be used with CM-SA Skin Analysis software.

The CM-700d Spectrophotometer is compatible with SpectraMagic NX software to record measurements and provide a more comprehensive color analysis, as well as Colibri software to formulate color recipes for various applications. For dermatological applications, the CM-700d can also be used with CM-SA Skin Analysis software.

The following specifications are included with this instrument: di: 8°, de: 8° (diffused illumination, 8° viewing angle), SCI (specular component included)/SCE (specular component excluded) selectable with automatic switching (Conforms to CIE No. 15, ISO 7724/1, DIN5033 Teil7, ASTM E 1164, and JIS Z 8722)

General

IEC 68-2-9, Basic Environmental Testing Procedures-Part 2:Guidance for Solar Radiation Testing

IEC 68-2-9, Basic Environmental Testing Procedures-Part 2:Guidance for Solar Radiation Testing

ISO 4892-1, Plastics-Methods of exposure to laboratory light sources-Part 1: General Guidance

ASTM G151, General Guidelines for Exposure of Nonmetallic Materials

ASTM G155, Xenon-Arc Test Apparatus for Exposure of Nonmetallic Materials

Automotive

SAE J2412, Accelerated Exposure of Automotive Interior Trim Components Using a Controlled Irradiance Xenon-Arc Apparatus

SAE J2527, Accelerated Exposure of Automotive Exterior Materials Using a Controlled Irradiance Xenon-Arc Apparatus

Coatings

SO 11341, Paints and varnishes - Artificial weathering and exposure to artificial radiation - Exposure to filtered xenon-arc radiation

SO 11341, Paints and varnishes - Artificial weathering and exposure to artificial radiation - Exposure to filtered xenon-arc radiation

ASTM D3451, Testing Coating Powders and Powder Coatings

ASTM D3794, Testing Coil Coatings

ASTM D6577, Standard Guide for Testing Industrial Protective Coatings

ASTM D6695, Xenon-Arc Exposures of Paints and Related Coatings

GB 1865, Paints and varnishes - Artificial weathering and exposure to artificial radiation- Filtered xenon arc radiation

JIS K 5600-7-7, Testing Methods for Paints - Part 7: Long-Period Performance of Film - Section 7: Accelerated Weathering (Exposure to Filtered Xenon Arc)

MPI: #113, Exterior, Waterborne, Pigmented Elastomeric Coating

MS 133: Part F14, Methods of Test for Paints & Varnishes: Part F14: Artificial Weathering & Exposure to Artificial Radiation – Exposure to Filtered Xenon Arc Radiation (ISO 11341)

Pharmaceutical

ICH Guideline, Stability Testing: Photostability Testing of New Drug Substances and Products

Plastics

ISO 4892-2, Plastics-Methods of exposure to laboratory light sources-Part 2: Xenon-arc sources

ISO 4892-2, Plastics-Methods of exposure to laboratory light sources-Part 2: Xenon-arc sources

JIS K 7350-2, Plastics-Methods of exposure to laboratory light sources-Part 2: Xenon-arc sources

DIN EN 513, Unplasticized polyvinyl chloride (PVC-U) profiles for fabrication of windows & doors

ASTM D1248 , Polyethylene Plastic Extrusion Materials for Wire and Cable

ASTM D2565 , Xenon-Arc – Plastics for Outdoor Applications

ASTM D4101, Polypropylene Plastic Injection and Extrusion Materials

ASTM D4459 , Xenon-Arc – Plastics for Indoor Applications

ASTM D5071, Xenon-Arc Exposure of Photodegradable Plastics

ASTM D6662, Plastic Lumber Decking Boards

Geotextiles

ASTM D4355, Deterioration of Geotextiles to UV Light

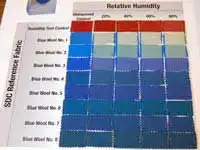

Textiles

AATCC TM 16, Colorfastness to Light

AATCC TM 169,Weather Resistance of Textiles: Xenon Lamp Exposure

GB/T-8430, Textiles - Tests for colorfastness - Colorfastness to artificial weathering: Xenon arc fading lamp test

IS: 2454, Indian Standard- Method for Determination of Colour Fastness of Textile Materials to Artificial Light (Xenon Lamp)

Printing Inks/ Artists' Materials/ Paper

ISO 11798, Information and documentation – Permanence of writing, printing & copying on paper

ISO 11798, Information and documentation – Permanence of writing, printing & copying on paper

ISO 12040, Graphic Technology - Prints and printing inks

ISO 18909, Imaging Materials – Processed photographic colour films and paper prints

ASTM D3424, Lightfastness of Printed Matter

ASTM D4303 , Lightfastness of Artists' Pigments

ASTM D5010, Testing Printing Inks & Related Materials

ASTM D6901, Standard Specification for Artists' Colored Pencils

ASTM F2366, Lightfastness of Ink Jet Prints Exposed to Window Filtered Daylight

Roofing

ASTM D4434, Poly Vinyl Chloride Sheet Roofing

ASTM D4637, EPDM Sheet Used in Single-Ply Roof Membrane

ASTM D4798, Xenon-Arc – Bituminous Materials

ASTM D4811, Nonvulcanized Rubber Sheet Used as Roof Flashing

ASTM D5019, Reinforced Non-Vulcanized Polymeric Sheet

ASTM D6083, Liquid Applied Acrylic Coatings Used in Roofing

Rubber

ISO 3865, Rubber, Vulcanized or Thermoplastic – Methods of test for staining on contact with organic materials

ISO 3865, Rubber, Vulcanized or Thermoplastic – Methods of test for staining on contact with organic materials

ISO 4665, Rubber, Vulcanized or Thermoplastic – Resistance to weathering

Adhesives

ASTM D904, Exposure of Adhesive Specimens to Artificial Light

ASTM C1442, Conducting Tests on Sealants Using Artificial Weathering Apparatus

ASTM C1501, Standard Test Method for Color Stability of Building Construction Sealants

Sealants

ASTM C1442, Conducting Tests on Sealants Using Artificial Weathering Apparatus

ASTM C1442, Conducting Tests on Sealants Using Artificial Weathering Apparatus

ASTM C1501, Color Stability of Sealants

Packaging

ASTM D6551, Accelerated Weathering of Pressure-Sensitive Tapes by Xenon Arc

Should you need additional information about CRT Laboratories' Weather Exposure testing capabilities please contact us via our RFQ Form or call us at (714) 283-2032.